Ultriva support specialist Lori McNeely recently hosted a training webinar highlighting the various ways MRP systems work with Ultriva. The webinar included information about publishing Forecasted Gross Requirements so that suppliers can view the information in the Ultriva portal – eliminating the need to send regular spreadsheets back and forth. McNeely also discussed how Ultriva can be utilized for the MRP firm orders generated by the ERP system, allowing for time-saving consolidation of supplier demand and fulfillment activities into one common system.

Forecast errors are costly, whether having too little or too much inventory; the additional time supply chain professionals spend correcting the orders to suppliers has a bottom-line impact as well. Ultriva is committed to helping manufacturers move away from forecasts to a demand-driven manufacturing and supply chain environment.

The webinar was offered to over 280 supply chain professionals in the automotive, aerospace, medical devices, electronic components, fitness equipment, pharmaceutical, and manufacturing industries. During the well-attended webinar the attendees were asked questions related to forecasts. McNeely’s first webinar survey question was, “How accurate do you think the forecast for your company usually is?”

The results were:

- 0-20% accurate (chosen by 8%)

- 21-40% accurate (chosen by 17%)

- 41-60% accurate (chosen by 29%)

- 61-80% accurate (chosen by 38%)

- 81-100% accurate (chosen by 8%)

With 54% of the respondents claiming less than 60% forecast accuracy, it is not surprising supply chain professionals have to spend a large portion of the day making additional corrective action spreadsheets and providing them to suppliers.

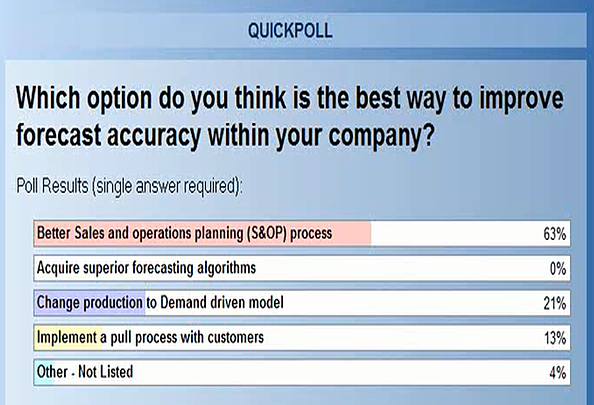

The second forecast-based question McNeely asked during the webinar was, “Which option do you think is the best way to improve forecast accuracy within your company?”

The results were:

- Better sales and operations planning (S&OP) process (chosen by 63%)

- Acquire superior forecasting algorithms (chosen by 0%)

- Change production to Demand Driven Model (chosen by 21%)

- Implement a pull process with customers (chosen by 13%)

- Other – not listed (chosen by 4%)

The number one response by industry professionals was “better sales and operation planning.” This is not surprising, as the the tendency is to believe an improved plan will lead to the promised land. However as we all know planning numbers are still a guess, and planners cannot “plan” for the unknown (economic slowdown or natural disasters.) S&OPs is often based on forecasts from the customers and sales people. Getting improved numbers will not magically make those numbers any more accurate.

The two choices, “changing production to a demand-driven model” and “implementing a pull process,” (33% combined), though not a majority, bodes well for the future. This is in line with what Ultriva is witnessing with its prospects in the field. Ultriva is winning by helping companies to move in this direction.

How Ultriva Helps supplier collaboration with MRP driven parts:

Ultriva provides all information to suppliers electronically – Forecasts, Order Exceptions and Firm Orders, eliminating the need for a series of emails with Excel attachments. For parts which are dual or multi-sourced, Ultriva automatically distributes the gross requirements based on the defined percent split for that particular part or component.

Normally MRP planned orders need an approval from the buyers prior to becoming a purchase order (PO) that can be sent to suppliers. Ultriva allows the plans to be loaded whenever the MRP is run. Buyers can use the interactive tools to process approval and release POs to suppliers.

MRP firm orders generated by MRP are also shared in real-time with suppliers via a Collaborative Supply Portal. Having a real-time view of parts, shared between buyer and all suppliers, without the threat of a spread sheet or fax coming with different numbers, establishes trust among all partners.

To learn more about Forecast Errors, please see our newsletter.