Current supply chain management systems often lack the tools necessary to quickly and cost effectively react to the constant stream of changes in customer demand, production schedules, and supply deficiencies common in global markets. Relying on different systems with multiple tools is often expensive, time-consuming, and inefficient. The best technology solutions must support true collaboration and execution between manufacturers and supply chain partners to enable seamless performance and increase revenue.

Many companies which have traditional supply chain problems such as excess inventory, stock outs, long lead times and planning emergencies, frequently turn to lean manufacturing principles to provide solutions. Based in Cupertino, California, Ultriva has distinct products that follow the lean supply chain from the raw material purchase through to the customer to ensure lean distribution, lean factory, and lean supply chain best-practices.

Six years ago in August, Ultriva was asked by McKesson  Automation to identify areas for improvement. An onsite diagnostic visit was scheduled and Ultriva took a read of McKesson’s supply chain ‘vital signs’. The result was an initial six-week pilot plan with several focus areas. Narayan Laksham, founder and CEO of Ultriva noted, “We had to identify supply-chain inefficiencies and implement lean inventory management. While McKesson had a solid foundation with its Six Sigma program and manual kanban systems, our initial investigations revealed the efficiency of their supply chain could be improved.”

Automation to identify areas for improvement. An onsite diagnostic visit was scheduled and Ultriva took a read of McKesson’s supply chain ‘vital signs’. The result was an initial six-week pilot plan with several focus areas. Narayan Laksham, founder and CEO of Ultriva noted, “We had to identify supply-chain inefficiencies and implement lean inventory management. While McKesson had a solid foundation with its Six Sigma program and manual kanban systems, our initial investigations revealed the efficiency of their supply chain could be improved.”

Like many manufacturers, it was imperative to eliminate the use of spreadsheets for exchanging information with suppliers, in favor of an electronic closed-loop system. Ultriva had to ensure that errors were fixed and the scalability limitations associated with the manual system, eliminated. Finally Ultriva had to address disconnects in the information flow between order entry, manufacturing shop floor, and accounts payable.

That pilot program was completed, and now six years later, the majority of McKesson suppliers and nearly all of the dollar value of all in-bound parts are run through Ultriva’s system. McKesson now has a collaborative platform where suppliers are connected; it enables all kanban signals to be tracked and traced.

Visibility is Paramount

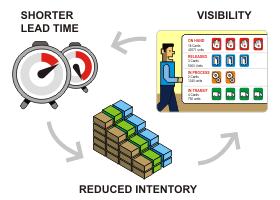

One of the operational benefits Ultriva brings to McKesson is much better visibility into the supply chain. Materials managers can see what was ordered, when it was shipped, when it arrived, when it was used, and when it was paid. The result is purchasing and accounts payable personnel now ‘manage by exception’, and free up valuable time and resources.

By encouraging all its raw materials suppliers to tap into the portal, Ultriva allows McKesson to realize a greater than 10% improvement on inventory turns AND a 50% reduction in supply chain administrative costs. Improved communication between the shop floor and suppliers has been the norm for the past six years giving McKesson a sharpened competitive edge through faster delivery of custom products. Shortages for JIT (just-in-time) items have been reduced to less than 1% of deliveries at McKesson, thanks to the Ultriva solution.

Ultriva Growth Continues

Ultriva continues to experience strong customer adoption including accelerated momentum in key vertical segments such as aerospace and defense, medical device and healthcare. Recently the company delivered a major upgrade to its product offering with a module that incorporates innovative social media concepts, an integrated 'Inventory Optimization Tool' and a 'Collaborative Request For Quotation' (RFQ). These solutions are targeted for manufacturers building complex products that require many components and a long lead time supply base.

The company has achieved impressive milestones including 240% growth in profitability, and a 24% increase in license revenue. These achievements are due in part to the establishment of a centralized support center to provide free technical and application support for customers. Ultriva has strategic partnerships including the Kaizen Institute, with over 350 consultants worldwide promoting continuous improvement methodologies

Laksham was enthusiastic, noting, "Our global customers select Ultriva to help them achieve maximum inventory velocity through demand-driven supply chains. In 2013 we are emphasizing expansion into Japan, Brazil, and Europe to meet demand from existing and potential customers."

Ultriva empowers leading industrial, automotive, healthcare, aerospace and defense businesses to operate more effectively and collaboratively by providing real time visibility and targeted actionable intelligence into inventory and material flows. Ultriva’s cloud-based platform leverages and seamlessly integrates with leading ERP and MRP systems, to deliver an end to end pull based replenishment model for the 21st century.