Dedicated inventory locations, while not required, are much easier to establish and maintain when a part is on supplier eKanban for two reasons. First, with supplier eKanban the supplier is required to ship materials in standard lot and container sizes which often dictate the type of storage. Secondly, maximum inventory levels are more predictable with eKanban allowing you to plan dedicated storage space for each item. Maximum inventory for an eKanban item = (Total # of kanbans in loop) x (standard kanban lot size).

According to Nandu Gopalun, Professional Services leader with Upland, Ultriva by Upland provides loop size variability. He outlined the distinct advantage that can be achieved with dedicated inventory locations. The grocery store always keeps items in the same place making the shopping experience easier. Similarly, loop size variability helps the material handler to handle the inventory so they do not have to chase the parts needed.

Read More

Topics:

kanban,

inventory,

ekanban,

loop,

inventory location,

maximum inventory

For the past seventeen years Ultriva by Upland has implemented successful supplier eKanban programs.

Read More

Topics:

kanban,

ekanban,

optimization

SuppliersOf.com is a software evaluation platform with the goal to eliminate the time spent searching for suppliers and to help you bullet-proof your supply chain. The company and website was founded on the principles of keeping things as lean as possible and getting features and capabilities out in the market as quickly as possible. Recently, the website wrote the following series of articles to introduce Lean thinking concepts, how they apply to supply chains and how Ultriva’s tools help implement lean ideas and extract value. Here is the first article in its entirety.

Read More

Topics:

supply chain,

kanban,

Ultriva,

lean manufacturing

The biggest challenge to any organization, whether manufacturing or distribution, is the availability of the right material at the right place at the right time. Companies invest enormous amount of resources - technology, people and time - to accomplish this goal. Supply chain segmentation is the buzz word that is being commonly touted for planning and managing this inventory. Once you segment your supply chain whether it is by customers or suppliers or high runners you need a strategy to manage them. The Kanban system is one such technique that is often used very effectively within the supply chain.

Read More

Topics:

supply chain,

kanban,

manufacturing,

inventory

Inventory is the lifeline of any manufacturing company. Customer service levels are gated by availability of Finished Goods. Production is highly dependent on availability of Work In Process and Raw Materials. Every manufacturer therefore spends a lot of time, effort and money to come up with an optimized inventory plan. A Material Replenishment Plan is what is needed to segment the items based on their consumption velocity and replenishment frequency. Some percentage of parts, which can vary based on the type of business, would be highly conducive to Electronic Kanban (eKanban) replenishment. In a made-to-order or made-to-stock manufacturing environment, we have seen these eKanban parts ranging from 40% to 90% of total spend.

Read More

Topics:

supply chain,

kanban,

manufacturing

Our last blog shared that Ultriva was the cover story in the manufacturing technology special edition issue of CIO Review. This feature article was authored by Raj Kumar and is titled, “Ultriva: Escalating Manufacturing Output Through Lean.” The author interviewed Narayan Laksham, Ultriva’s founder and CEO. This second part of the story features Ultriva real-world success in the manufacturing space. Here is part two of the article:

Read More

Topics:

supply chain,

kanban,

manufacturing,

Ultriva,

lean manufacturing

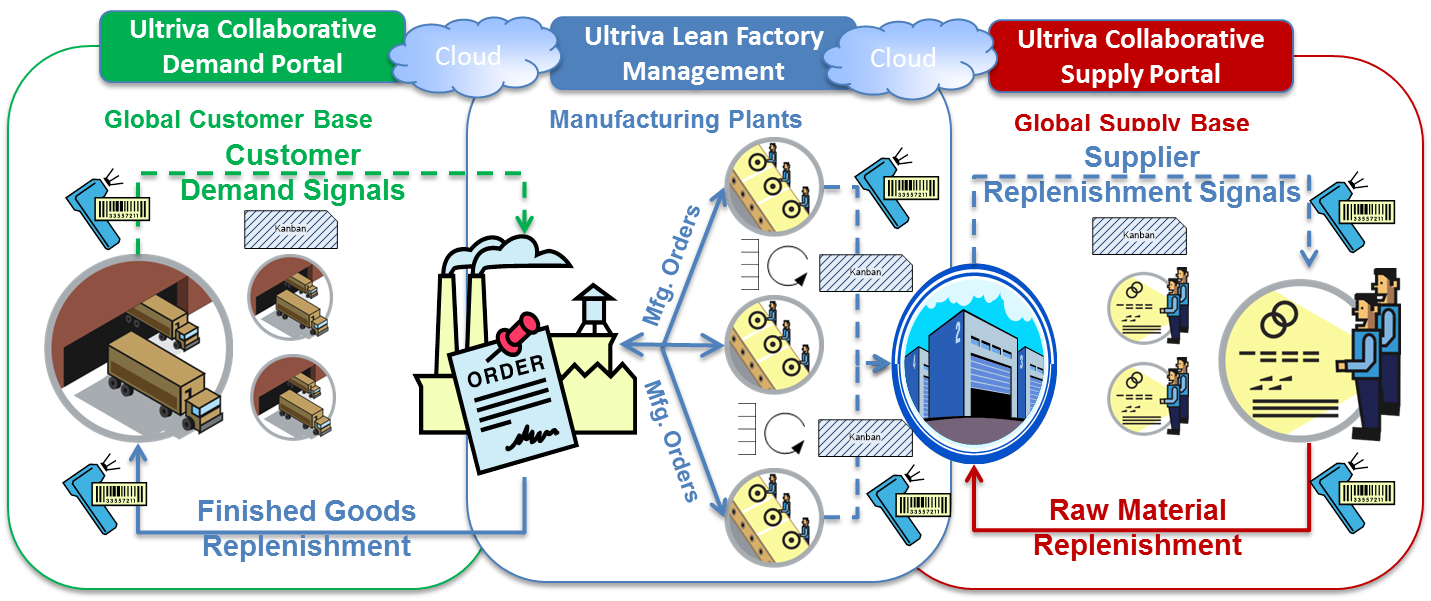

Recently, Ultriva, the leader in collaborative supply chain solutions, was the cover story in the current October issue of CIO Review. This issue was the manufacturing technology special edition. The feature article was authored by Raj Kumar and is titled, “Ultriva: Escalating Manufacturing Output Through Lean.” The author interviewed Narayan Laksham, Ultriva’s founder and CEO. During the course of the interview, Laksham explained how he applied lean principles to the supply chain processes and developed a solution that triumphs over the traditional Material Requirements Planning (MPR) systems and delivers more value. Here is part one of the article:

Read More

Topics:

supply chain,

kanban,

manufacturing,

Ultriva,

lean manufacturing

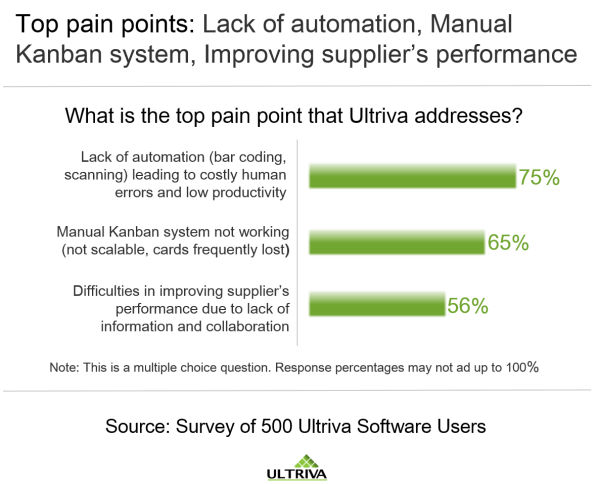

It is no secret that our SCM (supply chain management) software helps supply chain experts solve their pain points. In order to better serve our existing and prospective customers, we wanted to know specifically how Ultriva customers value the technology. This type of thinking is not new for Ultriva, we constantly incorporate customer feedback into our new enhancements and features, mostly recently in version 7.7. Voice of the customer (VOC) is what drives the people and product at Ultriva.

Read More

Topics:

supply chain,

kanban,

manufacturing,

Ultriva

Third party logistics providers (3PL) offer a variety of services, but the primary function of these organizations can be summarized as providing transportation, warehousing, and management of inventory for another company. Some companies handle inventory on consignment. Consignment stock is often defined as inventory owned by one party (in this case the “Supplier”), but held by another (the “3PL”). This risk rests with the first party, and do not get paid until the goods are sold (in this case the third player, the manufacturing “Company”).

Read More

Topics:

supply chain,

kanban,

inventory,

Ultriva

Manufacturing companies must uncover opportunities to reduce inventory to stay competitive. One way to reduce excess inventory (without the risk of stocking-out of important parts) is to determine an optimal replenishment cycle. This can be done by identifying which parts would benefit from an eKanban loop replenishment system.

Read More

Topics:

supply chain,

kanban,

inventory,

Ultriva