This is second in a series of articles by SuppliersOf.com, which is a software evaluation platform with the goal to eliminate the time spent searching for suppliers and to help bullet-proof your supply chain. The company and website was founded on the principles of keeping things as lean as possible and getting features and capabilities out in the market as quickly as possible. Recently, the website wrote the following series of articles to introduce Lean thinking concepts, how they apply to supply chains and how Ultriva’s tools help implement lean ideas and extract value. Here is the second article below.

Imagine a world where you deliver your final product to your customer after having just completed it, whether this is obtaining it from your suppliers or whether you've just assembled it. In this world its easy to see that shelves and shelves of inventory are only serving as buffers for the incapability of being able to operate just-in-time.

Read More

Topics:

manufacturing,

inventory,

Ultriva,

lean manufacturing

The biggest challenge to any organization, whether manufacturing or distribution, is the availability of the right material at the right place at the right time. Companies invest enormous amount of resources - technology, people and time - to accomplish this goal. Supply chain segmentation is the buzz word that is being commonly touted for planning and managing this inventory. Once you segment your supply chain whether it is by customers or suppliers or high runners you need a strategy to manage them. The Kanban system is one such technique that is often used very effectively within the supply chain.

Read More

Topics:

supply chain,

kanban,

manufacturing,

inventory

Manufacturers are working in an increasingly global and complex supply chain environment. Moreover, manufacturers are under pressure to introduce products more rapidly and to optimize costs, quality, and efficiency. Narayan Laksham, Ultriva’s founder and CEO notes that “The closest any manufacturer can get to the magic bullet is supply chain visibility. Supply chain visibility is needed to achieve manufacturers’ goal of inventory availability and improved service levels.”

Read More

Topics:

supply chain,

manufacturing,

inventory

Inventory is the lifeline of any manufacturing company. Customer service levels are gated by availability of Finished Goods. Production is highly dependent on availability of Work In Process and Raw Materials. Every manufacturer therefore spends a lot of time, effort and money to come up with an optimized inventory plan. A Material Replenishment Plan is what is needed to segment the items based on their consumption velocity and replenishment frequency. Some percentage of parts, which can vary based on the type of business, would be highly conducive to Electronic Kanban (eKanban) replenishment. In a made-to-order or made-to-stock manufacturing environment, we have seen these eKanban parts ranging from 40% to 90% of total spend.

Read More

Topics:

supply chain,

kanban,

manufacturing

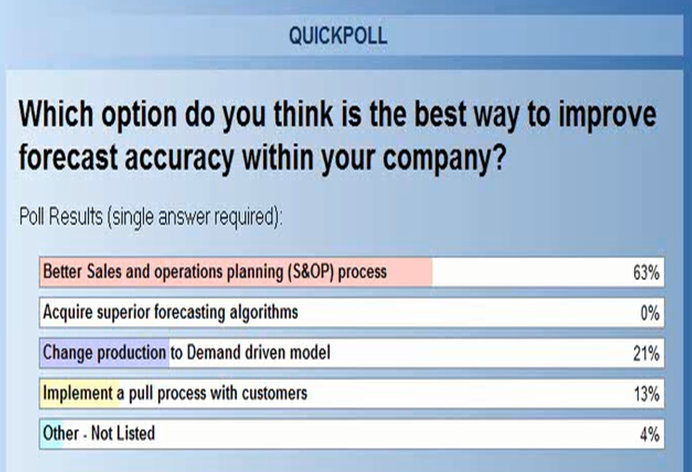

Manufacturing companies often use a Material Requirements Planning (MRP) forecast as a basis for Sales and Operations Planning (S&OP). However, MRP and supplier forecasting produce more problems in the supply chain than they solve. Errors in shipping, receiving or inventory reporting, or production schedule adjustments, change MRP data. Often the numbers cannot be quickly updated. Gartner Research Analysts recommends manufacturing companies to engage with customers and suppliers to establish a pull process from Finished Goods to Raw Materials. This is how Gartner defines End to End (E2E) Pull replenishment.

Read More

Topics:

supply chain,

manufacturing,

inventory,

end-to-end pull,

E2E Pull

Ultriva support specialist Lori McNeely recently hosted a training webinar highlighting the various ways MRP systems work with Ultriva. The webinar included information about publishing Forecasted Gross Requirements so that suppliers can view the information in the Ultriva portal – eliminating the need to send regular spreadsheets back and forth. McNeely also discussed how Ultriva can be utilized for the MRP firm orders generated by the ERP system, allowing for time-saving consolidation of supplier demand and fulfillment activities into one common system.

Forecast errors are costly, whether having too little or too much inventory; the additional time supply chain professionals spend correcting the orders to suppliers has a bottom-line impact as well. Ultriva is committed to helping manufacturers move away from forecasts to a demand-driven manufacturing and supply chain environment.

Read More

Topics:

supply chain,

manufacturing,

inventory,

lean manufacturing

This past summer Chad Smith, a Supply Chain expert and co-founder of the Demand Driven Institute presented a webinar with Ultriva about consumption-based replenishment. Smith is the co-author of Orlicky’s Material Requirements Planning, third edition (ISBN 978-07-175563-4) which suggested the result of MRP’s shortcomings and/or poor implementation is that companies have chronic and frequent shortages at various stages of the production, procurement, and fulfillment cycles.

Smith went on to say these chronic and frequent shortages tend to lead to three main effects:

Read More

Topics:

supply chain,

manufacturing,

inventory

This past summer Chad Smith, a Supply Chain expert and co-founder of the Demand Driven Institute presented a webinar with Ultriva about consumption-based replenishment. Smith is the co-author of Orlicky’s Material Requirements Planning, third edition (ISBN 978-07-175563-4) who suggested, “A solution must be deployed that allows companies to plan effectively while maintaining or increasing flexibility. Most global manufacturers, enterprise resource planning (ERP) software companies and manufacturing consultants seem to ignore the obvious path….Instead, the most common approach is to chase symptoms and propose incomplete and even disastrous solutions that either overcomplicate or oversimplify planning, execution, and control systems with less than desirable results.”

Read More

Topics:

supply chain,

manufacturing,

inventory

This past summer Chad Smith, a Supply Chain expert and co-founder of the Demand Driven Institute presented a webinar with Ultriva about consumption-based replenishment. Smith is the co-author of Orlicky’s Material Requirements Planning, third edition (ISBN 978-07-175563-4) who suggested, “Many manufacturers and supply chains face a huge dilemma related to their operational strategy and tactics. To put it bluntly, the world of ‘push and promote’ is dead. Gone are the days when a company could use the past to predict the future, build products to that forecast, and have any hope that the market would want what they produced. Companies that continue in this mode will see continual erosion in their market share and bottom-line performance until that company simply goes out of business. Additionally, rules and tools that were developed under those conditions must be reexamined and rebuilt for the circumstance of today.”

Read More

Topics:

supply chain,

manufacturing,

inventory

CIO Review has chosen Ultriva for its 20 Most Promising Manufacturing Technology Solution Providers. The positioning is based on Ultriva’s solutions that help manage the supply chain and improve the inventory velocity of leading industrial manufacturing, healthcare, aerospace and logistics firms.

Read More

Topics:

supply chain,

manufacturing,

Ultriva,

lean manufacturing