Gartner, Inc. (NYSE: IT), (www.gartner.com), the world's leading information technology research and advisory company, has made a compelling case as to why manufacturers should integrate with the demand side to streamline their supply chain. They call this process as “End to End Pull (E2E)” replenishment. This is clearly a paradigm shift compared to the constant focus on improving the planning or forecasts using better and superior algorithms.

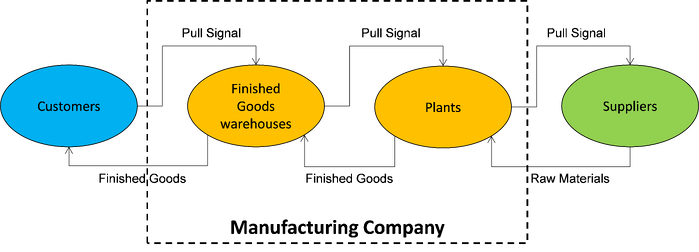

In its simplest form, Gartner is recommending the following model:

As shown above the pull loops are set up between the preceding and succeeding locations. This can be expanded to as many loops (tiers) as necessary depending on the business process of the manufacturers. For example, in the most extensive situation the tiers could be Retailer, Regional Warehouses, Central warehouses, Distribution centers, manufacturing plants, component manufactures, 3PLs, suppliers etc.

The primary goal of the E2E process is to schedule manufacturing production based on customer demand instead of forecasts while raw materials and components usage at the manufacturing facilities should drive replenishment to the upstream supply chain. This is also commonly known as “consumption driven replenishment” or “Electronic Kanban loops”.

Underlying the above process is an ability to have real time collaboration with the customers and suppliers. On-premise solutions, like MRP and ERP, do a fabulous job for inside the four walls of business. E2E on the other hand deals largely with outside the four walls of business.

What are the minimal requirements for a solution to establish the E2E process?

- A collaborative transactional portal that allows a manufacturing company’s customers and suppliers to interact in real time.

- Allow customers to send their demands, forecasts, plans and real time consumptions

- Allow suppliers to receive their purchase orders, Kanban signals, forecasts and MRP releases electronically through a portal

- Allow suppliers to print bar coded or RFID tagged labels for shipments

- Allow customers and suppliers to view respective performance levels

- Allow right sizing of inventory at each transaction points based on actual usage.

- Provide guidance to improve inventory velocity at the finished goods and raw materials

- Provide seamless interfaces to company’s ERP/MRP systems for keeping the data in sync.

How does E2E process improve the business?

- Allows manufacturing companies to reduce the customer lead times while improving service levels

- Carry the right mix of inventory to eliminate part shortages for the production

- Gain multi-tier visibility across the supply chain

- Improve inventory turns across Finished Goods, Work In Process and Raw Materials

- Get actionable information to manage exceptions

- Facilitate continuous improvement through real time metrics and analytics

- Ability to resize the inventory levels based on change in demands and usage

Ultriva has deployed this type of solution across many large customers worldwide. If you are interested in understanding what is E2E process or wish to integrate your customers and suppliers, please contact me.