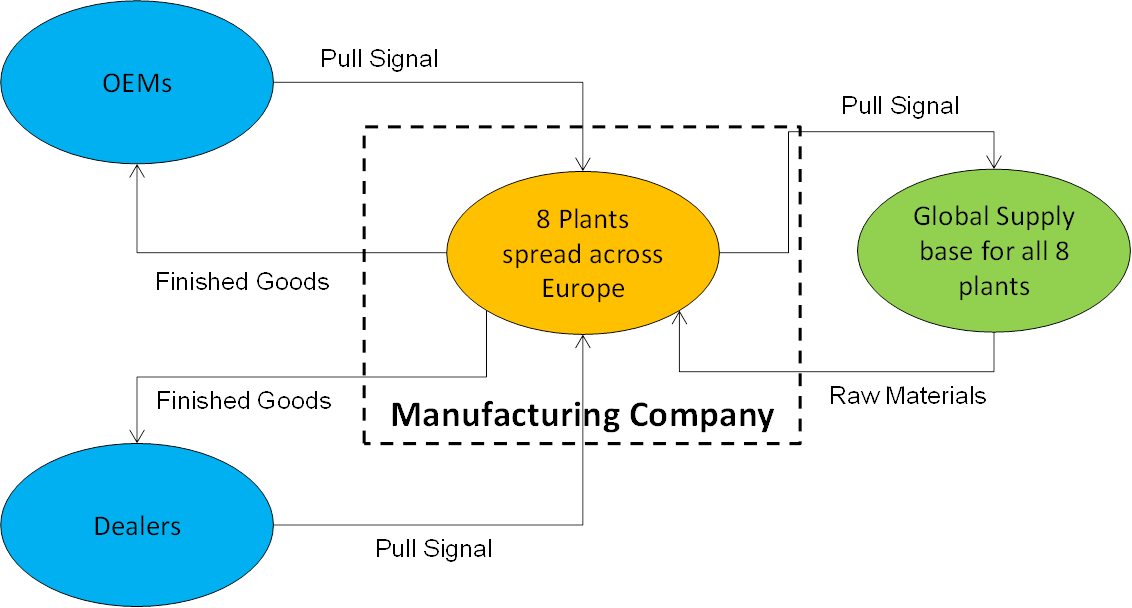

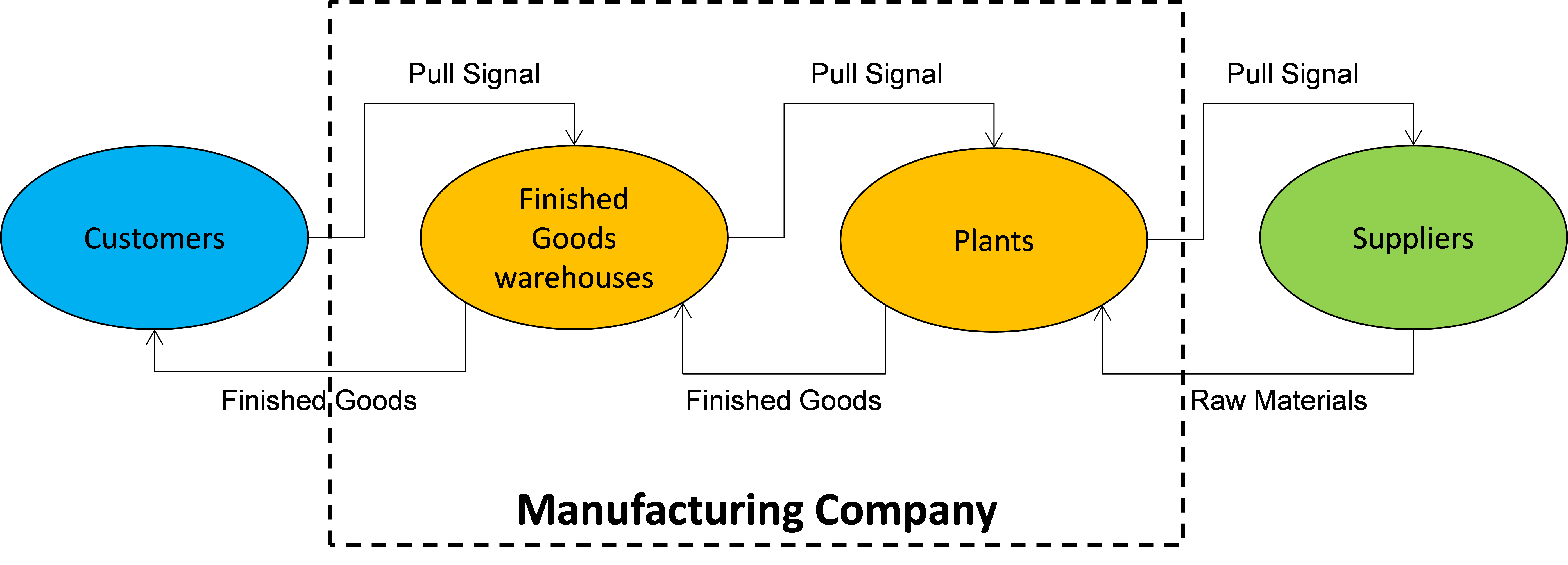

Manufacturing companies often use a Material Requirements Planning (MRP) forecast as a basis for Sales and Operations Planning (S&OP). However, MRP and supplier forecasting produce more problems in the supply chain than they solve. Errors in shipping, receiving or inventory reporting, or production schedule adjustments, change MRP data. Often the numbers cannot be quickly updated. Gartner Research Analysts recommends manufacturing companies to engage with customers and suppliers to establish a pull process from Finished Goods to Raw Materials. This is how Gartner defines End to End (E2E) Pull replenishment.

Read More

Topics:

supply chain,

manufacturing,

inventory,

end-to-end pull,

E2E Pull

Warehouse’s inventory at an all-time high, choosing a location for storage is tougher than ever. Demand for space is causing prices to go up, and manufacturers want to make sure they are still getting top notch service, especially when expenditures are higher than previous levels. DC Velocity reported U.S. warehousing costs spiked in 2013 as retailers, incented by low interest rates and inventory carrying

Read More

Topics:

inventory,

lean manufacturing,

end-to-end pull

Multi-national management organizations usually turn to improved best-practice technology solutions when one of two circumstances occurs: rapid growth requiring improved throughput capacity or serious quality-control issues, often under the scrutiny of regulatory compliance or threat of litigation. Both these challenges produce lower customer satisfaction if the correct products are not received in a timely, safe, and accurate manner.

Read More

Topics:

supply chain,

lean manufacturing,

end-to-end pull,

E2E Pull

Once a technology solution has been tested and vetted by a multi-national, multi-plant operation, it is rolled out enterprise-wide. There are many reasons why this approach, tiptoeing into solutions with obvious bottom-line improvements, takes time.

Read More

Topics:

supply chain,

collaboration,

lean manufacturing,

end-to-end pull,

E2E Pull

The medical technology industry employs over 500,000 workers according to the Medical Device Manufacturers Association (MDMA.) The industry supports approximately 1.4 million additional jobs, for 1.9 million high-paying positions, and generated $113 billion in payroll, with an average salary over $84,000. According to Ernst and Young, the average earning for public med-tech companies is 6%.

Read More

Topics:

supply chain,

kanban,

lean manufacturing,

end-to-end pull,

E2E Pull

Continuing our blog posts on the End to End pull replenishment system, we will be tackling the most common of the eight requirements; the critical need for manufacturers to collaborate and integrate with their upstream supply chain.

Read More

Topics:

supply chain,

collaboration,

end-to-end pull,

E2E Pull

Every product release, whether it is a major version or a dot release, is an exciting time for a software development team. As the development manager leading the Ultriva 7.6 release, we had to go through a different kind of rigor as the enhancements were spread across multiple application modules.

Some of the key features covered in 7.6 version include auto generation of Purchase Orders in to PDFs, streamlining of production sequencing, inventory cost analysis report, an improved Kanban board and auto resizing wizard. But the feature that is closest to my heart (as I was responsible for its design and development) was Advanced Bill of Lading (BOL).

Read More

Topics:

Ultriva,

end-to-end pull,

E2E Pull,

Oracle

Last week we discussed the first requirement on why a collaborative transactional portal is a must have for establishing End to End (E2E) pull replenishment. Feel free to refer to the original blog that described E2E Pull and all the requirements.

Read More

Topics:

collaboration,

inventory,

end-to-end pull,

E2E Pull

The First Requirement for E2E

Last week, I wrote a blog highlighting the clear need for a cloud-based SaaS solution to establish the “End to End Pull” process across manufacturing companies (or E2E pull process or just E2E). In that blog, eight basic requirements for developing an E2E pull model were listed.

Read More

Topics:

manufacturing,

end-to-end pull,

E2E Pull

Gartner, Inc. (NYSE: IT), (www.gartner.com), the world's leading information technology research and advisory company, has made a compelling case as to why manufacturers should integrate with the demand side to streamline their supply chain. They call this process as “End to End Pull (E2E)” replenishment. This is clearly a paradigm shift compared to the constant focus on improving the planning or forecasts using better and superior algorithms.

Read More

Topics:

manufacturing,

end-to-end pull,

E2E Pull