McKesson, the leading pharmaceutical distributor providing medical supplies and healthcare IT and driving more than $120 billion in annual sales, engaged with Ultriva by Upland to perform an onsite diagnostic visit to evaluate McKesson's supply chain "vital signs.” This pilot program identified multiple areas for improvement.

Read More

Topics:

inventory,

lean manufacturing,

ekanban,

supplier kanban,

Supplier Collaboration,

pull,

six sigma,

supply chain visibility

A commercial truck manufacturer was tasked with eliminating waste in its manufacturing process as part of an enterprise-wide continuous improvement initiative. The solution has to implement Lean Manufacturing principles and a pull-based electronic inventory Kanban system.

Read More

Topics:

inventory,

lean manufacturing,

ekanban,

supplier kanban,

Supplier Collaboration,

pull,

supply chain visibility

This is second in a series of articles by SuppliersOf.com, which is a software evaluation platform with the goal to eliminate the time spent searching for suppliers and to help bullet-proof your supply chain. The company and website was founded on the principles of keeping things as lean as possible and getting features and capabilities out in the market as quickly as possible. Recently, the website wrote the following series of articles to introduce Lean thinking concepts, how they apply to supply chains and how Ultriva’s tools help implement lean ideas and extract value. Here is the second article below.

Imagine a world where you deliver your final product to your customer after having just completed it, whether this is obtaining it from your suppliers or whether you've just assembled it. In this world its easy to see that shelves and shelves of inventory are only serving as buffers for the incapability of being able to operate just-in-time.

Read More

Topics:

manufacturing,

inventory,

Ultriva,

lean manufacturing

SuppliersOf.com is a software evaluation platform with the goal to eliminate the time spent searching for suppliers and to help you bullet-proof your supply chain. The company and website was founded on the principles of keeping things as lean as possible and getting features and capabilities out in the market as quickly as possible. Recently, the website wrote the following series of articles to introduce Lean thinking concepts, how they apply to supply chains and how Ultriva’s tools help implement lean ideas and extract value. Here is the first article in its entirety.

Read More

Topics:

supply chain,

kanban,

Ultriva,

lean manufacturing

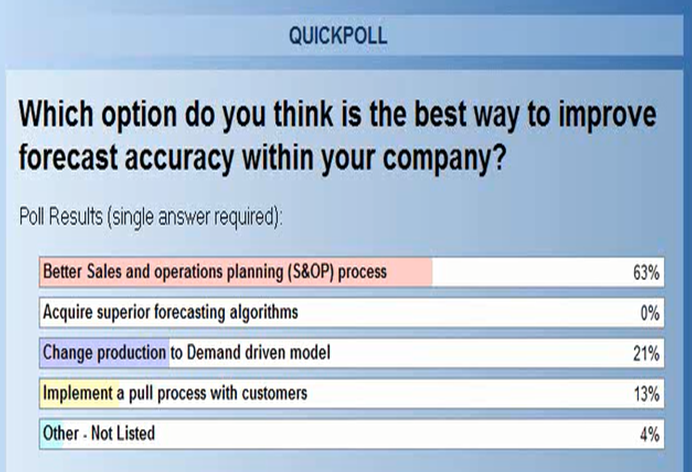

Ultriva support specialist Lori McNeely recently hosted a training webinar highlighting the various ways MRP systems work with Ultriva. The webinar included information about publishing Forecasted Gross Requirements so that suppliers can view the information in the Ultriva portal – eliminating the need to send regular spreadsheets back and forth. McNeely also discussed how Ultriva can be utilized for the MRP firm orders generated by the ERP system, allowing for time-saving consolidation of supplier demand and fulfillment activities into one common system.

Forecast errors are costly, whether having too little or too much inventory; the additional time supply chain professionals spend correcting the orders to suppliers has a bottom-line impact as well. Ultriva is committed to helping manufacturers move away from forecasts to a demand-driven manufacturing and supply chain environment.

Read More

Topics:

supply chain,

manufacturing,

inventory,

lean manufacturing

CIO Review has chosen Ultriva for its 20 Most Promising Manufacturing Technology Solution Providers. The positioning is based on Ultriva’s solutions that help manage the supply chain and improve the inventory velocity of leading industrial manufacturing, healthcare, aerospace and logistics firms.

Read More

Topics:

supply chain,

manufacturing,

Ultriva,

lean manufacturing

Last week I shared the insights of a CEO using Demand Driven Supply Chain methodologies profiled Chad Smith in Demand Driven Performance – Using Smart Metrics (Smith and Smith, McGraw-Hill, 2013). Smith is a co-founder and Partner at the Demand Driven Institute, an organization dedicated to proliferating demand driven methods globally. Smith serves as the Program Director of the International Supply Chain Education Alliance’s Certified Demand Driven Planner (CDDP) Program. Two months ago Chad Smith and I (Ultriva founder, Narayan Laksham) discussed the five components of DDMRP (Demand Driven Materials Resource Planning) at a well-attended webinar.

Read More

Topics:

supply chain,

inventory,

Ultriva,

lean manufacturing

Two months ago Chad Smith and I (Ultriva founder, Narayan Laksham) discussed the five components of DDMRP (Demand Driven Materials Resource Planning) at a well-attended webinar. Wanted to take this blog as an opportunity to dig a little deeper. Smith is the co-author of Demand Driven Performance – Using Smart Metrics (Smith and Smith, McGraw-Hill, 2013). He is a co-founder and Partner at the Demand Driven Institute, an organization dedicated to proliferating demand driven methods globally. Smith serves as the Program Director of the International Supply Chain Education Alliance’s Certified Demand Driven Planner (CDDP) Program.

Read More

Topics:

supply chain,

inventory,

Ultriva,

lean manufacturing

Our last blog shared that Ultriva was the cover story in the manufacturing technology special edition issue of CIO Review. This feature article was authored by Raj Kumar and is titled, “Ultriva: Escalating Manufacturing Output Through Lean.” The author interviewed Narayan Laksham, Ultriva’s founder and CEO. This second part of the story features Ultriva real-world success in the manufacturing space. Here is part two of the article:

Read More

Topics:

supply chain,

kanban,

manufacturing,

Ultriva,

lean manufacturing

Recently, Ultriva, the leader in collaborative supply chain solutions, was the cover story in the current October issue of CIO Review. This issue was the manufacturing technology special edition. The feature article was authored by Raj Kumar and is titled, “Ultriva: Escalating Manufacturing Output Through Lean.” The author interviewed Narayan Laksham, Ultriva’s founder and CEO. During the course of the interview, Laksham explained how he applied lean principles to the supply chain processes and developed a solution that triumphs over the traditional Material Requirements Planning (MPR) systems and delivers more value. Here is part one of the article:

Read More

Topics:

supply chain,

kanban,

manufacturing,

Ultriva,

lean manufacturing