Ultriva by Upland recently completed a comprehensive lean solution for a leading laboratory equipment manufacturing company which designs, manufactures, and sells scientific equipment and instruments to customers worldwide. It has approximately 39,000 employees globally and supplies customers within hospitals, research facilities, labs, and pharmaceutical companies.

Read More

Topics:

supply chain,

collaboration,

inventory,

ekanban,

Supplier Collaboration,

pull

Not much has changed with Supply Chain Management in the last two decades. MRP and ERP forecasts still rule the roost. When Supply Chain initiatives are undertaken, they usually involve improving the forecast.

Read More

Topics:

supply chain,

Cloud,

collaboration

Albert Einstein said intellectuals solve problems, geniuses prevent them. Built-in engineering rules allow customers to define rules on any event or action that occurs in the supply chain.

Read More

Topics:

supply chain,

collaboration,

Ultriva

Living in a world of speed, immediate accessibility, and instant gratification, consumer packaged goods (CPG) manufacturers have to procure raw materials, build components, assemble finished goods and physically ship them across the world. Challenged with shorter lead times and exploding finished goods SKUs, selling goods and procuring materials globally increase pressure to do more with less.

Read More

Topics:

collaboration,

inventory,

lean manufacturing

Everyone in the manufacturing industry wants to reduce inventory costs; easier said than done and there is no magic bullet. Simultaneously there is little appetite for inventory reduction solutions with a big price tag. The closest any manufacturer can get to the magic is supply chain visibility.

Read More

Topics:

supply chain,

manufacturing,

collaboration

Recently, Supply Chain Brain (SCB) published, “A Forecast for the Cloud in Supply Chain and Logistics.” Tom Boike, VP of supplier management with UPS, offered his perspective regarding the impact of cloud technology on the supply chain and logistics industry.

Read More

Topics:

supply chain,

Cloud,

collaboration

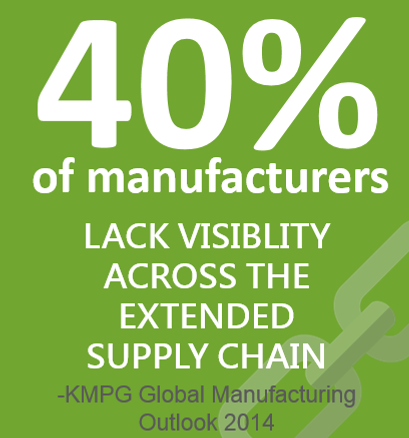

Recently, Forbes and KPMG International released a survey on manufacturing entitled ‘The 2014 Global Manufacturing Outlook: Performance in the Crosshairs.” The report is based on interviews with 460 senior manufacturing executives around the world.

The report contained four key findings:

- Manufacturers plan to invest in enhancing processes which increase profits

- Organizations will increase R&D spending, including outside collaborations and leveraging technology

- Supply Chain visibility remains a challenge.

- Manufacturers want to achieve a globally integrated supply chain and share real-time information with suppliers

Read More

Topics:

supply chain,

manufacturing,

collaboration

Integrating Supply Chain Execution Solutions for Real-Time Visibility to Leverage MRP/ERP Investments

During the last decade, I have personally visited over 150 manufacturing facilities worldwide to help manufacturing companies collaborate with suppliers and gain true supply chain visibility. Due to all this first-hand knowledge, it was a surprise to read Lora Cecere’s recent Forbes magazine article titled Bumps, Cracks and Opportunities reporting that large manufacturing companies, having spent a fortune on MRP systems (in this case SAP and JDA), still use spread sheets and other patches to get through the day. Cecere reports she has dealt with nine companies in one week alone who had to augment MRP forecasts. She shares how companies explained that they start using spread sheets after the forecast goes awry, and that many of the companies with whom she is working are not even using the costly MRP systems for supply chain planning.

Read More

Topics:

supply chain,

Cloud,

collaboration

A cost-effective supply chain collaboration between manufacturer and suppliers is paramount. Without that constraint addressed, all other benefits are pointless. Let us stipulate that cost-effective collaboration starts with electronic Kanban, or eKanban.

Read More

Topics:

supply chain,

kanban,

collaboration

Once a technology solution has been tested and vetted by a multi-national, multi-plant operation, it is rolled out enterprise-wide. There are many reasons why this approach, tiptoeing into solutions with obvious bottom-line improvements, takes time.

Read More

Topics:

supply chain,

collaboration,

lean manufacturing,

end-to-end pull,

E2E Pull