McKesson, the leading pharmaceutical distributor providing medical supplies and healthcare IT and driving more than $120 billion in annual sales, engaged with Ultriva by Upland to perform an onsite diagnostic visit to evaluate McKesson's supply chain "vital signs.” This pilot program identified multiple areas for improvement.

Read More

Topics:

inventory,

lean manufacturing,

ekanban,

supplier kanban,

Supplier Collaboration,

pull,

six sigma,

supply chain visibility

A commercial truck manufacturer was tasked with eliminating waste in its manufacturing process as part of an enterprise-wide continuous improvement initiative. The solution has to implement Lean Manufacturing principles and a pull-based electronic inventory Kanban system.

Read More

Topics:

inventory,

lean manufacturing,

ekanban,

supplier kanban,

Supplier Collaboration,

pull,

supply chain visibility

Ultriva by Upland recently completed a comprehensive lean solution for a leading laboratory equipment manufacturing company which designs, manufactures, and sells scientific equipment and instruments to customers worldwide. It has approximately 39,000 employees globally and supplies customers within hospitals, research facilities, labs, and pharmaceutical companies.

Read More

Topics:

supply chain,

collaboration,

inventory,

ekanban,

Supplier Collaboration,

pull

Dedicated inventory locations, while not required, are much easier to establish and maintain when a part is on supplier eKanban for two reasons. First, with supplier eKanban the supplier is required to ship materials in standard lot and container sizes which often dictate the type of storage. Secondly, maximum inventory levels are more predictable with eKanban allowing you to plan dedicated storage space for each item. Maximum inventory for an eKanban item = (Total # of kanbans in loop) x (standard kanban lot size).

According to Nandu Gopalun, Professional Services leader with Upland, Ultriva by Upland provides loop size variability. He outlined the distinct advantage that can be achieved with dedicated inventory locations. The grocery store always keeps items in the same place making the shopping experience easier. Similarly, loop size variability helps the material handler to handle the inventory so they do not have to chase the parts needed.

Read More

Topics:

kanban,

inventory,

ekanban,

loop,

inventory location,

maximum inventory

This is the third in a series of articles by SuppliersOf.com to introduce and discuss lean supply chain management. Previously discussed was having visibility on demand all the way through your customers to help eliminate surprises. This article focuses on providing visibility to suppliers.

Wouldn't the world be a better place if whenever you needed something, it would show up right where you need it? No more waiting, no more lead times, just hold out your hand it magically appears.

Read More

Topics:

supply chain,

inventory,

Ultriva

This is second in a series of articles by SuppliersOf.com, which is a software evaluation platform with the goal to eliminate the time spent searching for suppliers and to help bullet-proof your supply chain. The company and website was founded on the principles of keeping things as lean as possible and getting features and capabilities out in the market as quickly as possible. Recently, the website wrote the following series of articles to introduce Lean thinking concepts, how they apply to supply chains and how Ultriva’s tools help implement lean ideas and extract value. Here is the second article below.

Imagine a world where you deliver your final product to your customer after having just completed it, whether this is obtaining it from your suppliers or whether you've just assembled it. In this world its easy to see that shelves and shelves of inventory are only serving as buffers for the incapability of being able to operate just-in-time.

Read More

Topics:

manufacturing,

inventory,

Ultriva,

lean manufacturing

Inventory supply has a mutable nature, and can shift based upon demand, competition, trends and weather. Inventory management is critical. According to a 2014 Business Forward Foundation report, in the American automobile industry, “auto-makers penalize suppliers as much as $10,000 for every minute their shipments are late. Faced with these penalties, a supplier whose trucks are delayed will often hire a helicopter to deliver a substitute shipment.” Imagine the costs that can be accrued. Stock-outs can be devastating, but excess inventory is not a solution. How does a company manage risk while still meeting the needs of customers?

Read More

Topics:

supply chain,

inventory

A 2010 survey of supply chain executives identified demand variability as the biggest challenge. Five years later demand variability remains at the top of the list - EFT’s 2015 Chief Supply Chain Officer Strategy Report identified demand variability as one of the top three business challenges driving the supply chain agenda. Meeting the challenge of demand variability is critical to supply chain optimization and to your business.

Read More

Topics:

supply chain,

inventory,

Ultriva

The biggest challenge to any organization, whether manufacturing or distribution, is the availability of the right material at the right place at the right time. Companies invest enormous amount of resources - technology, people and time - to accomplish this goal. Supply chain segmentation is the buzz word that is being commonly touted for planning and managing this inventory. Once you segment your supply chain whether it is by customers or suppliers or high runners you need a strategy to manage them. The Kanban system is one such technique that is often used very effectively within the supply chain.

Read More

Topics:

supply chain,

kanban,

manufacturing,

inventory

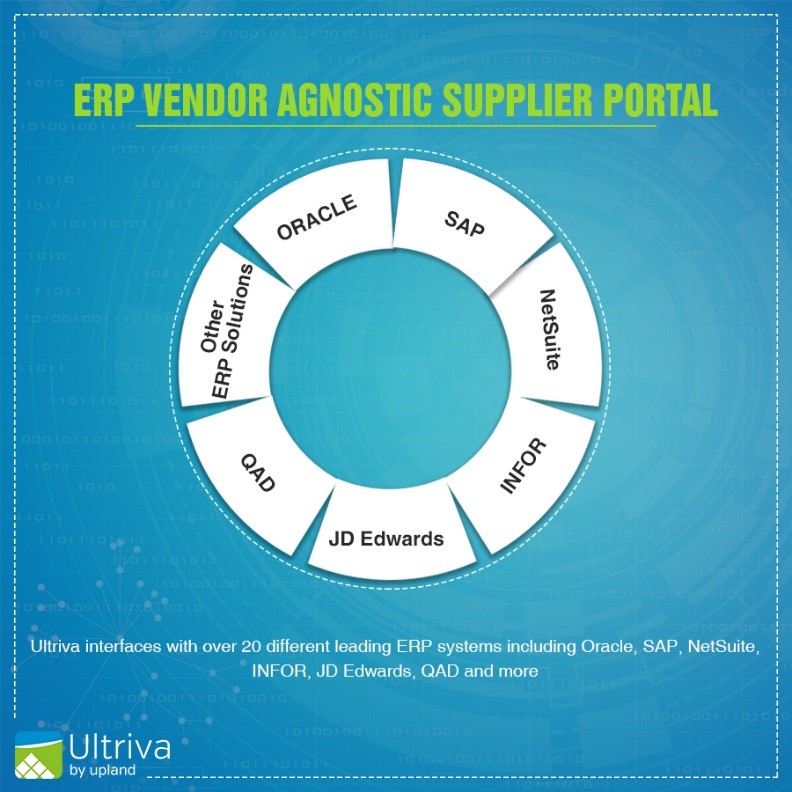

Manufacturers are working in an increasingly global and complex supply chain environment. Moreover, manufacturers are under pressure to introduce products more rapidly and to optimize costs, quality, and efficiency. Narayan Laksham, Ultriva’s founder and CEO notes that “The closest any manufacturer can get to the magic bullet is supply chain visibility. Supply chain visibility is needed to achieve manufacturers’ goal of inventory availability and improved service levels.”

Read More

Topics:

supply chain,

manufacturing,

inventory