Late last week, the Manufacturing & Technology eJournal report the following headline: American Women Vote Trane as Best Air Conditioning and Heating Brand for the Home. This was the second consecutive Women's Choice Award Seal of Recommendation that Trane, a leading global provider of indoor comfort systems and solutions and a brand of Ingersoll Rand (NYSE: IR), was awarded. In a national survey among more than 5,000 women who were asked to select the brands they would most highly recommend to others, and Trane came out on top.

Read More

Topics:

supply chain,

manufacturing,

collaboration,

Ultriva

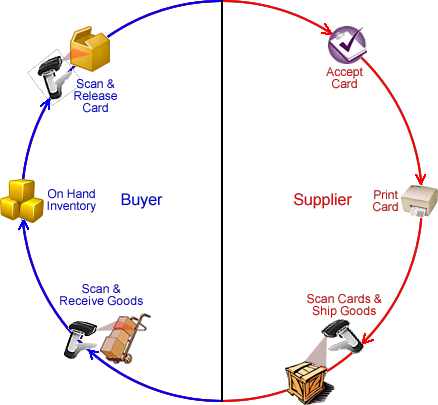

Current supply chain management systems often lack the tools necessary to quickly and cost effectively react to the constant stream of changes in customer demand, production schedules, and supply deficiencies common in global markets. Relying on different systems with multiple tools is often expensive, time-consuming, and inefficient. The best technology solutions must support true collaboration and execution between manufacturers and supply chain partners to enable seamless performance and increase revenue.

Read More

Topics:

kanban,

collaboration,

Ultriva,

lean manufacturing

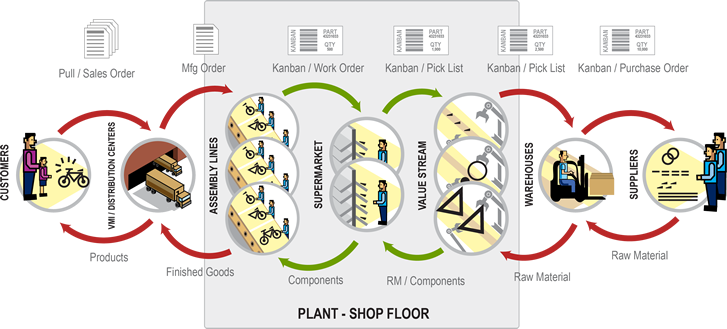

Kanban is at the core of many solutions, including Ultriva. That tells only a small part of the story which is about solutions that enhance the process and automates them across the value chain. Beyond kanban is an execution platform which sets up the pull process from the point of consumption to point of production. It means scheduling the production based on actual demand, real orders or pull signals.

Read More

Topics:

supply chain,

kanban,

manufacturing,

inventory

Lean quality concepts constantly reference continuous improvement. After a kaizen event and several months pass, there is often fatigue because the notion of continuously looking for better practices (en route to best-practices) is exhausting.

Read More

Topics:

kanban,

inventory,

lean manufacturing

The Gartner IT Glossary explains that, “Demand forecasting applications incorporate historical and predictive customer demand information into production line and sales quotas.” Sounds simple enough…not really. Matters become more complex when extending the definition to an end-to-end pull process…still trickier when sensing customer demand and synchronizing supply.

Read More

Topics:

supply chain,

kanban,

collaboration,

lean manufacturing

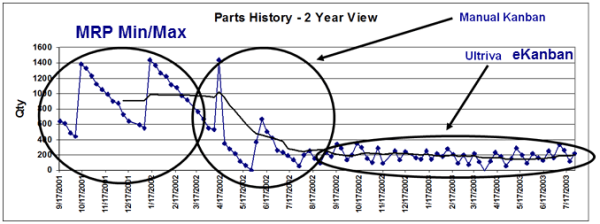

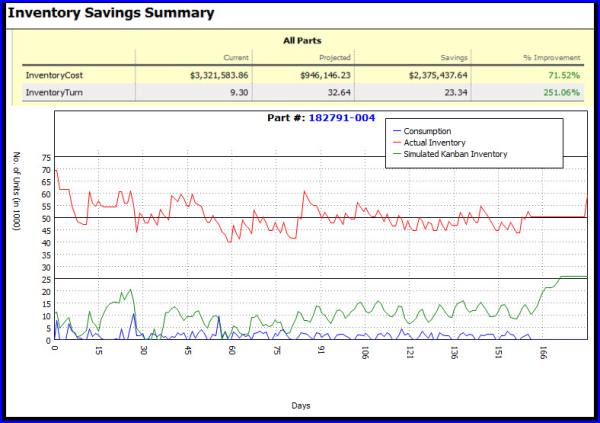

Introduction

Companies that use ERP and MRP systems are constantly looking for solutions to increase inventory turns, streamline the procurement process and improve supply chain agility. Many of these companies assume that the only way to reduce cost, lower risk or increase flexibility is to improve forecast accuracy. But various factors including customer demand variations, changing market conditions and questionable sales projections make it exponentially difficult to improve forecasting. One solution that most of these companies often don’t contemplate is moving away from a forecast based or MRP replenishment methodology to Electronic Kanban (eKanban) for high consumption items.

Read More

Topics:

supply chain,

kanban,

collaboration,

inventory

We all understand how difficult it is to change the wheels on a moving bus. If you've heard that analogy applied before, it was probably to justify why business transformation or a change in process is so difficult.

Read More

Topics:

supply chain,

kanban

Walk through any manufacturing facility and you’ll notice they all have the same type of charts displayed on the walls, bulletin boards, or electronic displays highlighting results of lean six sigma programs. The shop floor constantly runs Kaizens to improve factory-floor operations.

Surprisingly, most of the emphasis on the shop floor has been on streamlining production, relocating equipment, reducing production down time, and optimizing production capacity. Everything is focused on activities within the four walls of the factory shop floor. A very small percentage of these activities revolve around improving on-time-delivery, or improving supplier collaboration and material availability (i.e. processes that are occurring outside the facility).

Read More

Topics:

supply chain,

kanban,

collaboration,

lean manufacturing

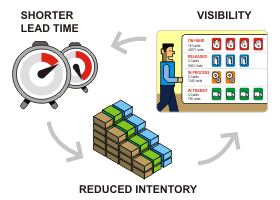

This is a common dilemma that constantly plagues supply chain professionals. The traditional supply chain paradigm supports the belief that reduction of inventory will lead to increase in part shortages and subsequently lower service levels. This paradigm is constantly being reinforced by credible sources such as the Wall Street Journal as evidenced in this WSJ article by Mark Gongloff where he seems to suggest that more inventory = more growth. However, this is just not true….under the new supply chain paradigm!

Read More

Topics:

supply chain,

collaboration,

inventory