Have you ever taken the time to evaluate the current-state of your material procurement process? If you have, there’s a good chance that you found the process to be executed by people in departmental silos trying to manage several complex and interrelated processes. You probably also recognized the large amount of analysis work required to make the right purchase decisions and the almost exclusive reliance on email, phone and fax to communicate and track individual purchase orders from release through to receipt of materials. If you haven’t taken the time evaluate your current-state material procurement process, you should. You might be surprised at what you find.

Read More

Topics:

supply chain,

collaboration

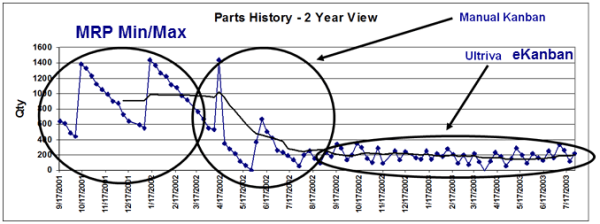

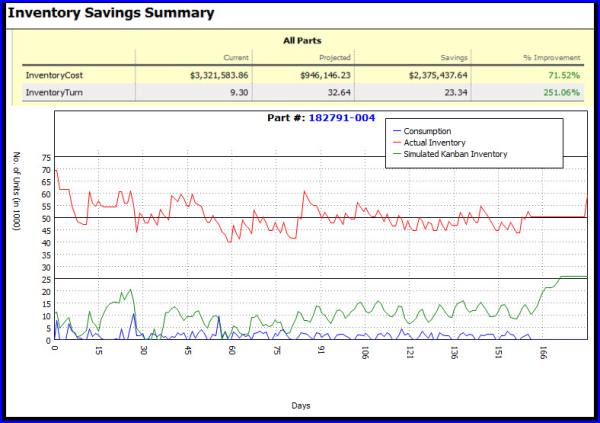

While manual shop floor kanban systems are common practice within manufacturing plants,manual supplier kanban systems are much rarer. One of the primary reasons for this is the difficulty faced when trying to scale a manual visual kanban system beyond the four walls of the plant. However, the operational and financial benefits of supplier kanban are so great that manufacturing firms are now looking to electronic supplier kanban systems (a.k.a. supplier ekanban) as the answer to their supplier kanban needs. The following list was compiled from feedback by Ultriva customers over the past 12 years of implementing successful supplier ekanban programs.

Read More

Topics:

supply chain,

kanban,

collaboration,

inventory

In today’s environment streamlining the supply chain is a high priority for most manufacturing companies. Purchased parts are typically 60% or more of the manufacturing cost. This puts tremendous pressure on materials and supply chain executives to drive these costs down, while at the same time improve on-time delivery. A proven approach to achieve those goals is to improve supply chain collaboration.

Read More

Topics:

supply chain,

manufacturing,

collaboration,

NetSuite,

Oracle

We all understand how difficult it is to change the wheels on a moving bus. If you've heard that analogy applied before, it was probably to justify why business transformation or a change in process is so difficult.

Read More

Topics:

supply chain,

kanban

For many years, Information Technology (IT) executives in manufacturing firms have been looking to their Enterprise Resource Planning (ERP) systems to help improve the operational and financial performance of their organizations. And why not, they’ve spent hundreds of thousands to millions of dollars on software licensing, a year or more implementing these systems and more than a few sleepless nights applying patches and updates from their ERP vendors. However, most of their efforts have been disproportionately focused on back office processes due to the inherent shortcomings of ERP systems to address the business requirements of manufacturing processes inside the four walls of the plant.

Read More

Topics:

supply chain,

manufacturing,

Oracle

CUPERTINO, Calif - February 6, 2012 – Ultriva Inc., a leader in Lean Supply Chain solutions today announced that Life Fitness Inc., a division of Brunswick Corporation has selected the Ultriva supply chain solution to manage its supply chain collaboration and electronic Kanban processes.

Read More

Topics:

supply chain,

Ultriva

How do you efficiently and cost effectively transition to a demand driven supply network without jeopardizing your position in industry or your commitments to your customers?

Read More

Topics:

supply chain,

lean manufacturing

What do distributed manufacturing, changing customer demand patterns, global supply chains, undesirable growth in inventory, and increasing pressure to reduce costs and improve profitability all have in common? These are just a few of the challenges faced by today’s manufacturing executives. Wouldn’t it be great if there was a system out there that could address each of the aforementioned challenges cost effectively and efficiently? Well there is, it’s called a pull system (a.k.a. kanban) and it has been around for a long time. Properly implemented, pull systems produce remarkable results. So why isn’t pull more pervasive in manufacturing? The simple reason is there have been more failures than successes.

Read More

Topics:

supply chain,

kanban,

Cloud,

manufacturing

Walk through any manufacturing facility and you’ll notice they all have the same type of charts displayed on the walls, bulletin boards, or electronic displays highlighting results of lean six sigma programs. The shop floor constantly runs Kaizens to improve factory-floor operations.

Surprisingly, most of the emphasis on the shop floor has been on streamlining production, relocating equipment, reducing production down time, and optimizing production capacity. Everything is focused on activities within the four walls of the factory shop floor. A very small percentage of these activities revolve around improving on-time-delivery, or improving supplier collaboration and material availability (i.e. processes that are occurring outside the facility).

Read More

Topics:

supply chain,

kanban,

collaboration,

lean manufacturing

This is a common dilemma that constantly plagues supply chain professionals. The traditional supply chain paradigm supports the belief that reduction of inventory will lead to increase in part shortages and subsequently lower service levels. This paradigm is constantly being reinforced by credible sources such as the Wall Street Journal as evidenced in this WSJ article by Mark Gongloff where he seems to suggest that more inventory = more growth. However, this is just not true….under the new supply chain paradigm!

Read More

Topics:

supply chain,

collaboration,

inventory