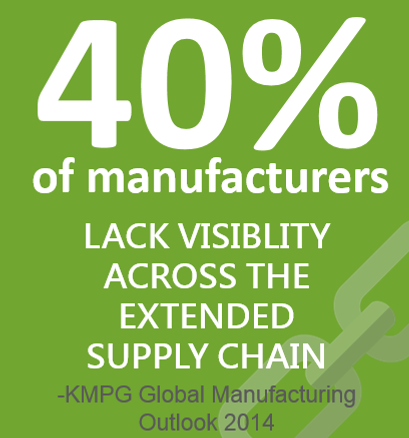

Recently, Forbes and KPMG International released a survey on manufacturing entitled ‘The 2014 Global Manufacturing Outlook: Performance in the Crosshairs.” The report is based on interviews with 460 senior manufacturing executives around the world.

The report contained four key findings:

- Manufacturers plan to invest in enhancing processes which increase profits

- Organizations will increase R&D spending, including outside collaborations and leveraging technology

- Supply Chain visibility remains a challenge.

- Manufacturers want to achieve a globally integrated supply chain and share real-time information with suppliers

Read More

Topics:

supply chain,

manufacturing,

collaboration

Manufacturing companies must uncover opportunities to reduce inventory to stay competitive. One way to reduce excess inventory (without the risk of stocking-out of important parts) is to determine an optimal replenishment cycle. This can be done by identifying which parts would benefit from an eKanban loop replenishment system.

Read More

Topics:

supply chain,

kanban,

inventory,

Ultriva

Integrating Supply Chain Execution Solutions for Real-Time Visibility to Leverage MRP/ERP Investments

During the last decade, I have personally visited over 150 manufacturing facilities worldwide to help manufacturing companies collaborate with suppliers and gain true supply chain visibility. Due to all this first-hand knowledge, it was a surprise to read Lora Cecere’s recent Forbes magazine article titled Bumps, Cracks and Opportunities reporting that large manufacturing companies, having spent a fortune on MRP systems (in this case SAP and JDA), still use spread sheets and other patches to get through the day. Cecere reports she has dealt with nine companies in one week alone who had to augment MRP forecasts. She shares how companies explained that they start using spread sheets after the forecast goes awry, and that many of the companies with whom she is working are not even using the costly MRP systems for supply chain planning.

Read More

Topics:

supply chain,

Cloud,

collaboration

Are you a manufacturing company that wishes to extend your existing business system to accomplish one or more of the following?

- Gain End to End Supply Chain Visibility (E2ESCV)

- Reduce your lead time by moving to a Demand Driven Manufacturing model

- Build trust in your supply chain through collaboration with suppliers and customers

- Migrate to electronic Kanban replenishment with suppliers for having the right part at the right place

- Increase your customer service levels by moving to consumption driven replenishment with your customers – OEMs, Distributors or Retailers.

Let Ultriva Lean Suite accomplish these goals and extend your investment in Oracle EBS

Read More

Topics:

supply chain,

Cloud,

manufacturing,

Oracle

Recently, Modern Materials Handling magazine published a case study of a pet supply company struggling with inventory. Warehouse workers had to physically bring the inventory to a computer to scan it, then send it on to the destination. The process was “cumbersome and inefficient.” The problem was solved by adding mobile workstations with scanning capabilities. There was a definite, measureable ROI, productivity increased by 40%, with the added benefit of freeing up workers. Warehouse employees now dedicate less time to product movement. Workers also use the mobile carts as label makers for pallets to save time instead of walking across the warehouse to the workstation to print.

Read More

Topics:

supply chain,

kanban,

manufacturing,

inventory,

Ultriva,

Oracle

Mid-May was a busy time for Ultriva. In addition to connecting with our users at our annual Customer Conference, we were an exhibitor at NetSuite’s SuiteWorld 2014. SuiteWorld is Netsuite’s annual user conference for customers, partners, media, and industry analysts in San Jose, California.

Read More

Topics:

supply chain,

Cloud,

manufacturing,

NetSuite,

Ultriva,

lean manufacturing

A cost-effective supply chain collaboration between manufacturer and suppliers is paramount. Without that constraint addressed, all other benefits are pointless. Let us stipulate that cost-effective collaboration starts with electronic Kanban, or eKanban.

Read More

Topics:

supply chain,

kanban,

collaboration

All of Ultriva is excited that we will be exhibiting at SuiteWorld 2014 in San Jose, California from May 12-15, 2014. The SuiteWorld Conference is expected to attract more than 6,000 NetSuite customers, partners, and developers from around the world. SuiteWorld is NetSuite’s largest user conference and Ultriva representatives will be showcasing their supply chain management solution which will complement NetSuite Cloud ERP. Attendees can visit Ultriva at booth #818.

Ultriva’s Lean Suite provides a collaborative platform for manufacturers to establish Electronic Kanban with their customers and suppliers. All the Ultriva modules – Inventory Optimization Tool (IOT), Customer Kanban, Supplier Kanban and Lean Factory Management, will exchange data seamlessly with NetSuite ERP.

Ultriva will feature a live demonstration of the Ultriva Inventory Optimization Tool with direct connectivity to NetSuite. This demonstration illustrates precisely how Ultriva extracts historical data from NetSuite and simulates potential inventory savings.

Read More

Topics:

supply chain,

Cloud,

manufacturing,

NetSuite

Often overlooked in lean manufacturing initiatives is the supply chain; in particular supplier replenishment. Global multi-national manufacturers can use supplier replenishment as the ultimate tool in lean manufacturing best-practices.

Read More

Topics:

supply chain,

manufacturing,

inventory,

lean manufacturing

Multi-national management organizations usually turn to improved best-practice technology solutions when one of two circumstances occurs: rapid growth requiring improved throughput capacity or serious quality-control issues, often under the scrutiny of regulatory compliance or threat of litigation. Both these challenges produce lower customer satisfaction if the correct products are not received in a timely, safe, and accurate manner.

Read More

Topics:

supply chain,

lean manufacturing,

end-to-end pull,

E2E Pull