Introduction

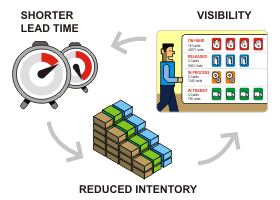

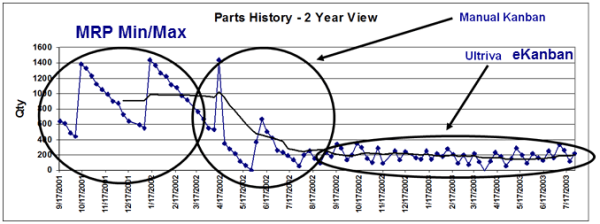

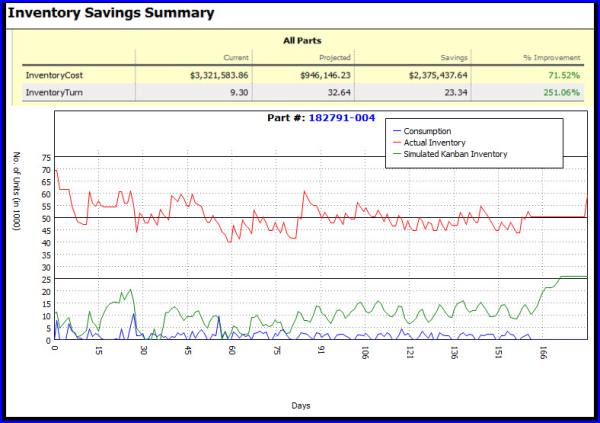

Companies that use ERP and MRP systems are constantly looking for solutions to increase inventory turns, streamline the procurement process and improve supply chain agility. Many of these companies assume that the only way to reduce cost, lower risk or increase flexibility is to improve forecast accuracy. But various factors including customer demand variations, changing market conditions and questionable sales projections make it exponentially difficult to improve forecasting. One solution that most of these companies often don’t contemplate is moving away from a forecast based or MRP replenishment methodology to Electronic Kanban (eKanban) for high consumption items.