Before too much time passes by, I’d like to express my heartfelt thanks to our customers who took time out of their busy schedules to attend this month’s user conference. Attendance was up over previous years, and we saw representation from a wider selection of companies, including Adams Thermal, CareFusion, Dixie Electric, Emerson, Exemplis, Genentech, Magellan, SonoSite, Specialized, Trane/IR, and Zurn.

Read More

Topics:

customer,

event

This is second in a series of articles by SuppliersOf.com, which is a software evaluation platform with the goal to eliminate the time spent searching for suppliers and to help bullet-proof your supply chain. The company and website was founded on the principles of keeping things as lean as possible and getting features and capabilities out in the market as quickly as possible. Recently, the website wrote the following series of articles to introduce Lean thinking concepts, how they apply to supply chains and how Ultriva’s tools help implement lean ideas and extract value. Here is the second article below.

Imagine a world where you deliver your final product to your customer after having just completed it, whether this is obtaining it from your suppliers or whether you've just assembled it. In this world its easy to see that shelves and shelves of inventory are only serving as buffers for the incapability of being able to operate just-in-time.

Read More

Topics:

manufacturing,

inventory,

Ultriva,

lean manufacturing

SuppliersOf.com is a software evaluation platform with the goal to eliminate the time spent searching for suppliers and to help you bullet-proof your supply chain. The company and website was founded on the principles of keeping things as lean as possible and getting features and capabilities out in the market as quickly as possible. Recently, the website wrote the following series of articles to introduce Lean thinking concepts, how they apply to supply chains and how Ultriva’s tools help implement lean ideas and extract value. Here is the first article in its entirety.

Read More

Topics:

supply chain,

kanban,

Ultriva,

lean manufacturing

Inventory supply has a mutable nature, and can shift based upon demand, competition, trends and weather. Inventory management is critical. According to a 2014 Business Forward Foundation report, in the American automobile industry, “auto-makers penalize suppliers as much as $10,000 for every minute their shipments are late. Faced with these penalties, a supplier whose trucks are delayed will often hire a helicopter to deliver a substitute shipment.” Imagine the costs that can be accrued. Stock-outs can be devastating, but excess inventory is not a solution. How does a company manage risk while still meeting the needs of customers?

Read More

Topics:

supply chain,

inventory

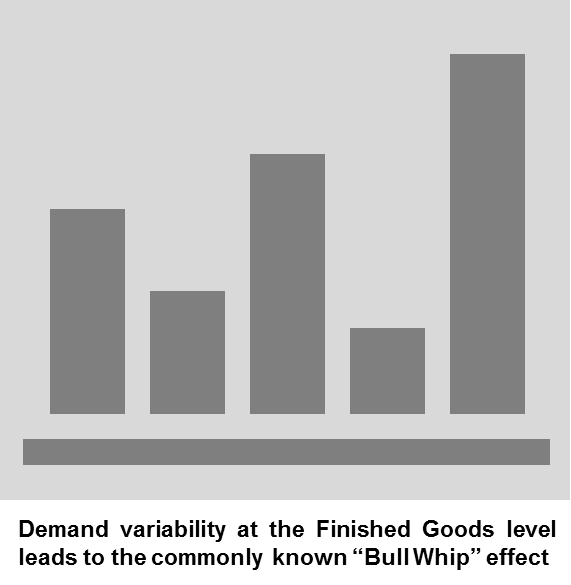

A 2010 survey of supply chain executives identified demand variability as the biggest challenge. Five years later demand variability remains at the top of the list - EFT’s 2015 Chief Supply Chain Officer Strategy Report identified demand variability as one of the top three business challenges driving the supply chain agenda. Meeting the challenge of demand variability is critical to supply chain optimization and to your business.

Read More

Topics:

supply chain,

inventory,

Ultriva

The biggest challenge to any organization, whether manufacturing or distribution, is the availability of the right material at the right place at the right time. Companies invest enormous amount of resources - technology, people and time - to accomplish this goal. Supply chain segmentation is the buzz word that is being commonly touted for planning and managing this inventory. Once you segment your supply chain whether it is by customers or suppliers or high runners you need a strategy to manage them. The Kanban system is one such technique that is often used very effectively within the supply chain.

Read More

Topics:

supply chain,

kanban,

manufacturing,

inventory

Manufacturers are working in an increasingly global and complex supply chain environment. Moreover, manufacturers are under pressure to introduce products more rapidly and to optimize costs, quality, and efficiency. Narayan Laksham, Ultriva’s founder and CEO notes that “The closest any manufacturer can get to the magic bullet is supply chain visibility. Supply chain visibility is needed to achieve manufacturers’ goal of inventory availability and improved service levels.”

Read More

Topics:

supply chain,

manufacturing,

inventory

Inventory is the lifeline of any manufacturing company. Customer service levels are gated by availability of Finished Goods. Production is highly dependent on availability of Work In Process and Raw Materials. Every manufacturer therefore spends a lot of time, effort and money to come up with an optimized inventory plan. A Material Replenishment Plan is what is needed to segment the items based on their consumption velocity and replenishment frequency. Some percentage of parts, which can vary based on the type of business, would be highly conducive to Electronic Kanban (eKanban) replenishment. In a made-to-order or made-to-stock manufacturing environment, we have seen these eKanban parts ranging from 40% to 90% of total spend.

Read More

Topics:

supply chain,

kanban,

manufacturing

Manufacturing companies often use a Material Requirements Planning (MRP) forecast as a basis for Sales and Operations Planning (S&OP). However, MRP and supplier forecasting produce more problems in the supply chain than they solve. Errors in shipping, receiving or inventory reporting, or production schedule adjustments, change MRP data. Often the numbers cannot be quickly updated. Gartner Research Analysts recommends manufacturing companies to engage with customers and suppliers to establish a pull process from Finished Goods to Raw Materials. This is how Gartner defines End to End (E2E) Pull replenishment.

Read More

Topics:

supply chain,

manufacturing,

inventory,

end-to-end pull,

E2E Pull

Not much has changed with Supply Chain Management in the last two decades. MRP and ERP forecasts still rule the roost. When Supply Chain initiatives are undertaken, they usually involve improving the forecast.

Read More

Topics:

supply chain,

Cloud,

collaboration